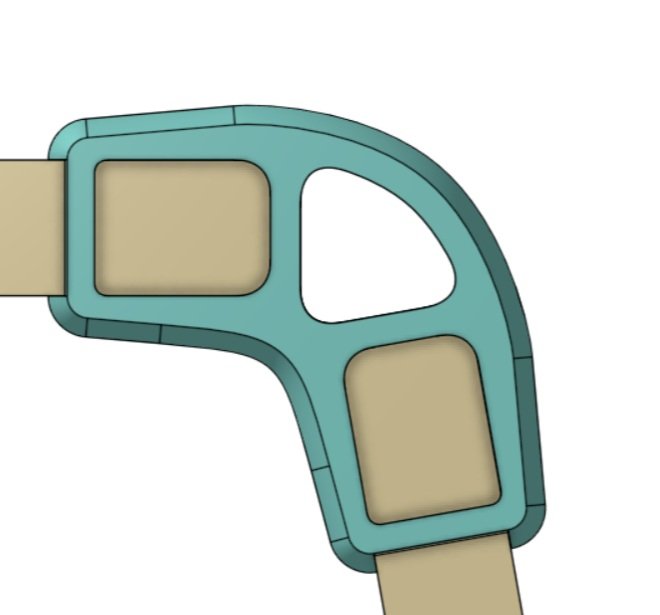

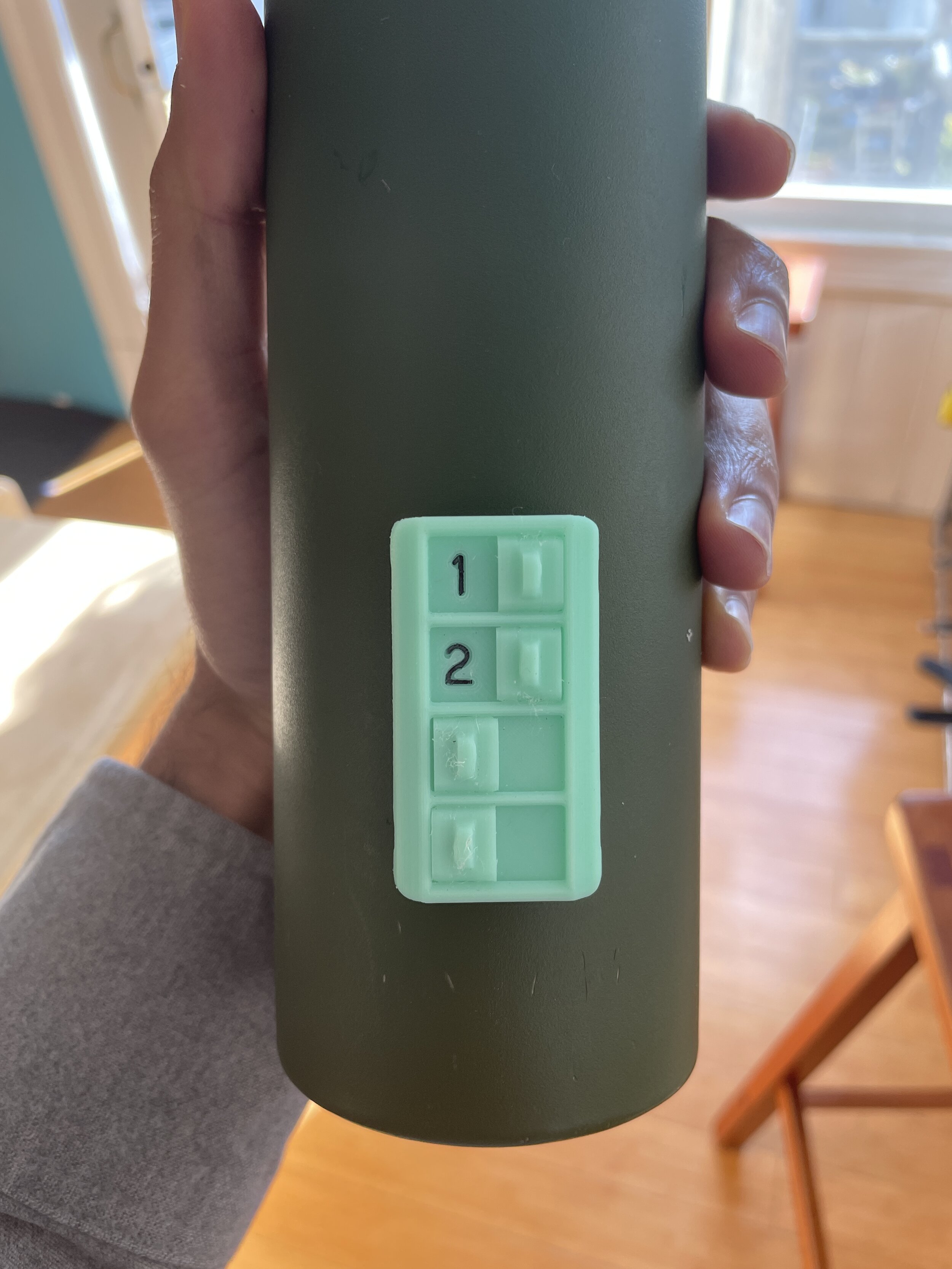

Had a new concept for a dog bowl stand. I don’t usually do big prints, but this was fun! Filled it with some old #9 Phillips screws I didn’t want (kudos to one of my friends for the idea. Can’t remember who.

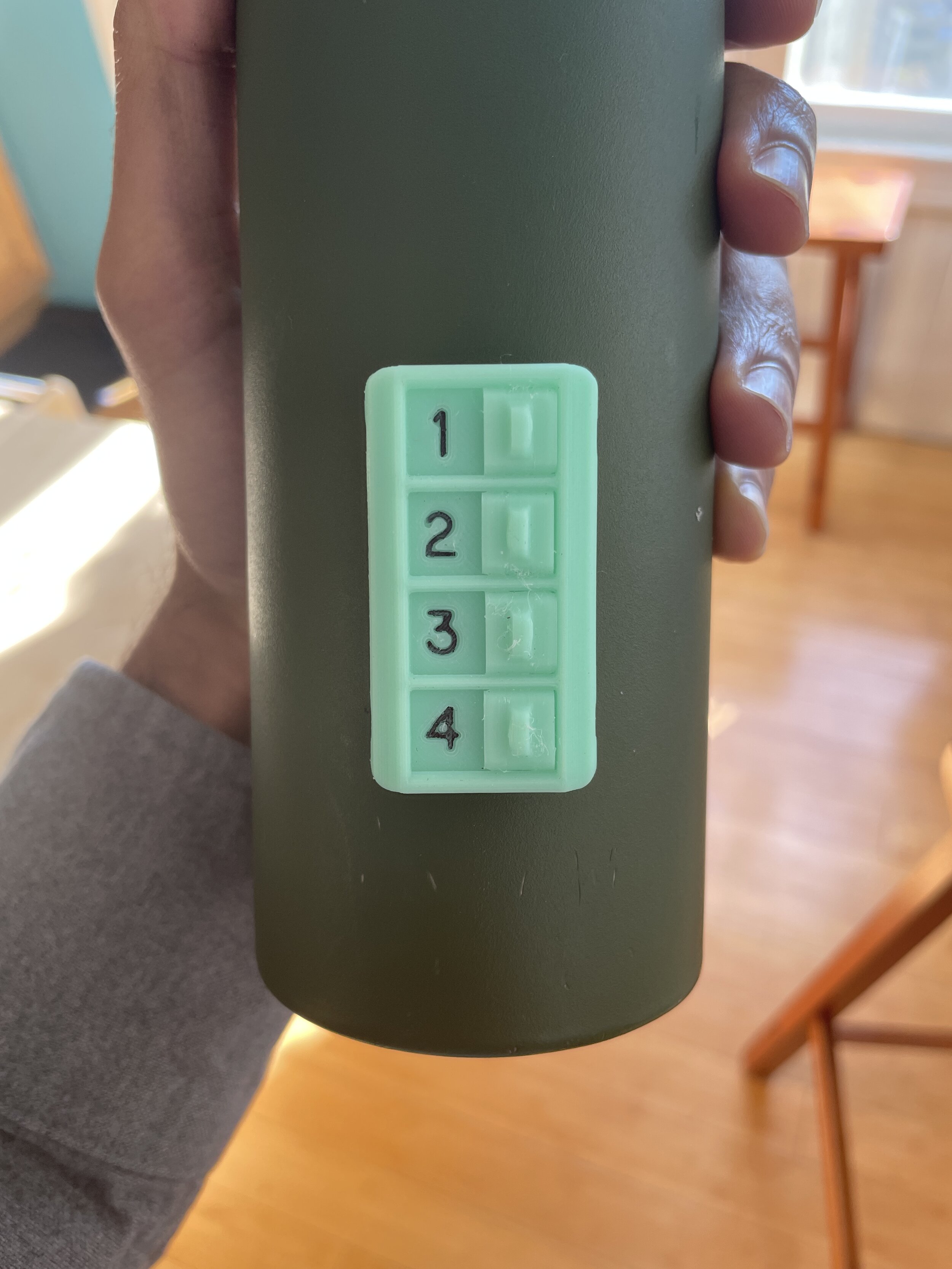

I didn’t sit out with the intention of sanding and painting this print, but I really messed up all the cosmetics when gluing it together. I was definitely playing it fast and loose with filling and sanding so it’s not perfect… But it’s done!

Couple coats of sandal filler, some plastic primer, some white paint, and some clearcoat. Might do a little bit more finishing like this in the future, we’ll see!